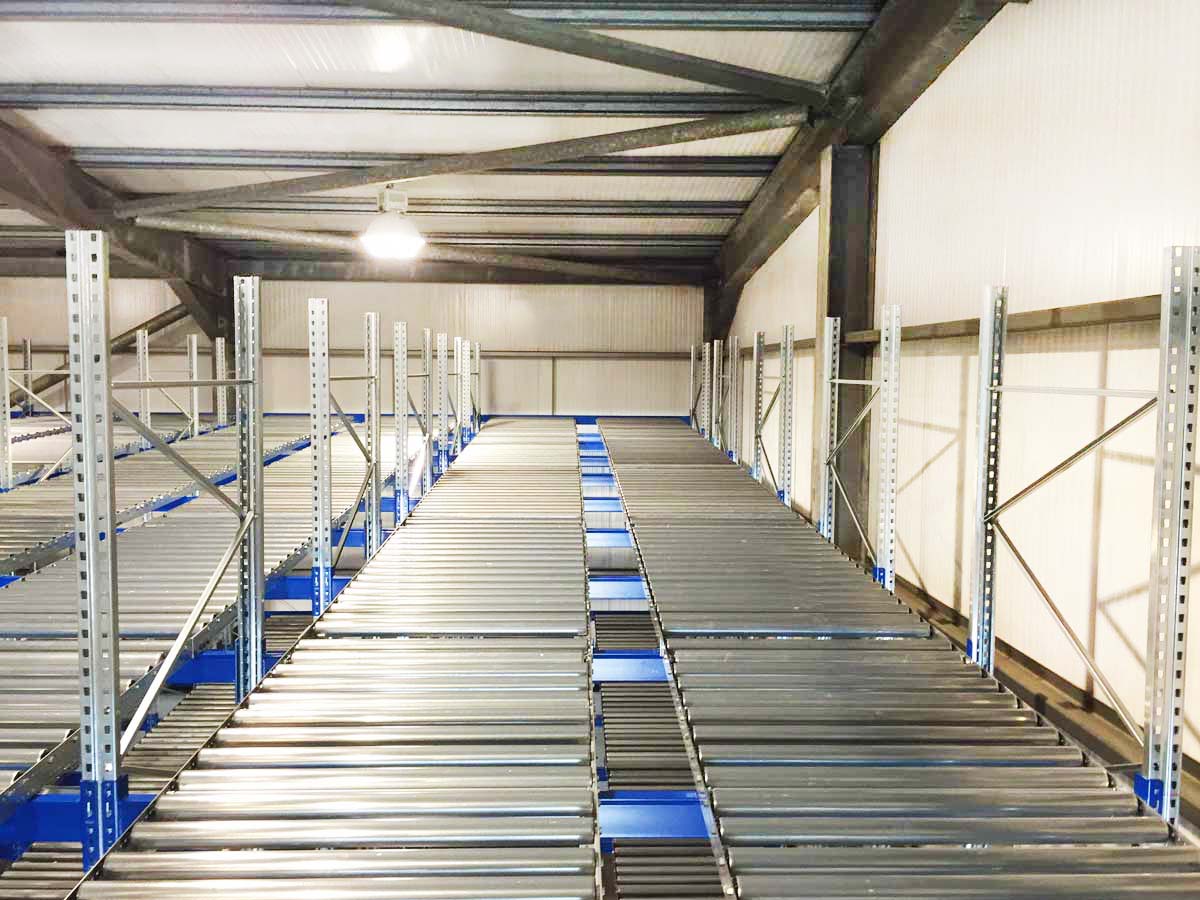

Pallet Live Storage

- With a pallet live storage system fewer aisles are needed. This increases your storage capacity considerably.

- Back-up stock can be stored in each lane facilitating order processing.

- Pallet live storage reduces travel time between locations and cost.

- The long storage lanes allow handling of large volumes of common products with live storage.

- Pallet live storage helps you reduce energy costs : Lighting is limited to the load and unload areas. The refrigerating costs in cold stores become a lot lower as they are related to the cubic volume of the warehouse.

Pallet Live storage systems:

FIFO (First-in / First-out)

Allied’s live storage system provides efficient and ultra-dense storage of palletised goods. The goods are inserted at the on-load face and travel down under the force of gravity. At the off-load face the pallets can be removed. With this system pallets are stored on the first-in/ first-out principle (FIFO).

LIFO (Last-in / First-out)

The Push back system, also realised with roller tracks, provides a last-in / first-out operation (LIFO). In this case the pallets are loaded and unloaded from the same side. The lift truck pushes the pallets into their storage location and they return under the force of gravity.

Thinking about using our Pallet Live Storage solutions?

Request a call back and let us help you.

Because we believe your project matters.