Client: Easons

Location: Dublin Airport Logistics Park, Co. Dublin

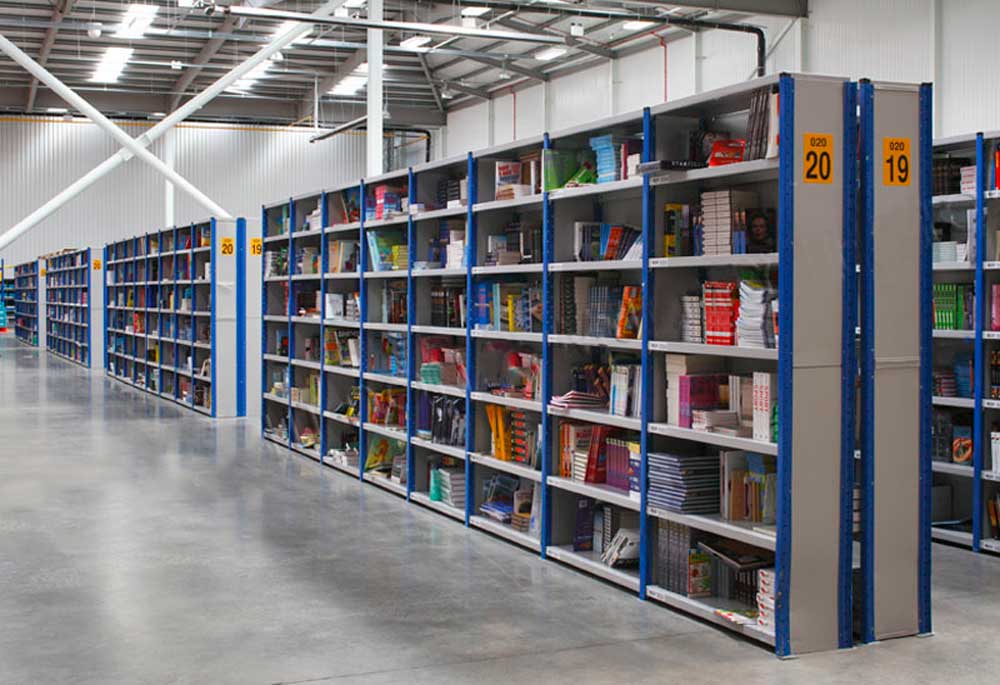

Product: Pallet Racking, Steel Shelving

Eason’s new state-of-the-art facility in Dublin Airport Logistics Park, Co. Dublin is over 140,000 square feet and was built to consolidate 6 separate distribution and storage sites under the one roof. The new facility is a fully automated warehouse that stores over 40,000 product lines, performs 20,000 picks per day, with over 300 deliveries to stores throughout Ireland and Northern Ireland.

The facility is fully integrated and controlled by sophisticated computer software, incorporating 3 separate Automated Storage and Retrieval Systems (ASRS). These systems are linked by powered driven roller conveyors, with belt driven conveyors to inclines. Allied installed narrow aisle and wide aisle pallet racking, storing over 6,000 pallets. The facility boasts over 5.25km of Allied adjustable shelving, and a vast array of accessories and key safety equipment, including picking deck levels within racks, safety barriers and anti-collapse mesh and protection equipment for the racking and warehouse facility.

“We would recommend Allied to any company looking for a professional partner who can deliver a project of this size and complexity, on time, meeting all health, safety and quality standards and within budget”

Tim Carpenter, Project Manager, Eason & Son

Both the pallet racking and shelving systems were designed to optimise the storage of goods of all sizes and weights. Planning aids used by Allied included 3-D computer modelling and warehouse simulation programs. The conventional pallet racking systems (both narrow and wide aisles) proved to be the best solution for this facility, where the need was to store palletised products with a range of product lines. Each pallet and product line can, therefore, be accessed directly and stock control is easily facilitated.

Allied’s project team consisted of CAD Designers, Engineers, Contracts Managers, and Installation Crews, all overseen by a Project Director.

The new facility was opened in 2007 and has made a significant contribution to improving the speed of order picking, numbers of deliveries and the overall efficiency of the operation.

“We work with manufacturers, wholesalers, retailers and end-users, collaborating on storage installations that range from simple to complex, very large to small. In every case, the quality of thinking, the attention to detail, the application of experience and knowlege is simply second-to-none”

Tim Evans, Director, Allied Ireland

Client: Easons

Location: Dublin Airport Logistics Park, Co. Dublin

Product: Pallet Racking, Steel Shelving

Eason’s new state-of-the-art facility in Dublin Airport Logistics Park, Co. Dublin is over 140,000 square feet and was built to consolidate 6 separate distribution and storage sites under the one roof. The new facility is a fully automated warehouse that stores over 40,000 product lines, performs 20,000 picks per day, with over 300 deliveries to stores throughout Ireland and Northern Ireland.

The facility is fully integrated and controlled by sophisticated computer software, incorporating 3 separate Automated Storage and Retrieval Systems (ASRS). These systems are linked by powered driven roller conveyors, with belt driven conveyors to inclines. Allied installed narrow aisle and wide aisle pallet racking, storing over 6,000 pallets. The facility boasts over 5.25km of Allied adjustable shelving, and a vast array of accessories and key safety equipment, including picking deck levels within racks, safety barriers and anti-collapse mesh and protection equipment for the racking and warehouse facility.

“We would recommend Allied to any company looking for a professional partner who can deliver a project of this size and complexity, on time, meeting all health, safety and quality standards and within budget”

Tim Carpenter, Project Manager, Eason & Son

Both the pallet racking and shelving systems were designed to optimise the storage of goods of all sizes and weights. Planning aids used by Allied included 3-D computer modelling and warehouse simulation programs. The conventional pallet racking systems (both narrow and wide aisles) proved to be the best solution for this facility, where the need was to store palletised products with a range of product lines. Each pallet and product line can, therefore, be accessed directly and stock control is easily facilitated.

Allied’s project team consisted of CAD Designers, Engineers, Contracts Managers, and Installation Crews, all overseen by a Project Director.

The new facility was opened in 2007 and has made a significant contribution to improving the speed of order picking, numbers of deliveries and the overall efficiency of the operation.

“We work with manufacturers, wholesalers, retailers and end-users, collaborating on storage installations that range from simple to complex, very large to small. In every case, the quality of thinking, the attention to detail, the application of experience and knowlege is simply second-to-none”

Tim Evans, Director, Allied Ireland

Do you need advice on your new project?

Request a call back and let us help you.

Keep in touch.